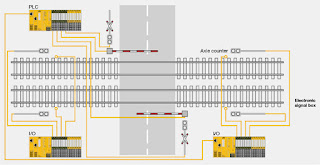

At Railtex 13, Pilz will present an automated half barrier level crossing demonstrator, with the PSS 4000-R Safety PLC System implementing control and signalling.

At Railtex 13, Pilz will present an automated half barrier level crossing demonstrator, with the PSS 4000-R Safety PLC System implementing control and signalling. Staff from the UK and other Pilz countries where successful use of the PSS 4000-R has been made will be available on the stand to talk about the benefits of PLC technology for the rail sector.

Previous safety solutions in the railway sector have largely used proprietary, specialist technology - much of it based around relay logic, however, this has often involved a lot of work for a one-off approval – particularly with regard to rail safety standards.

Components in the PSS 4000-R system (PLC header modules and modular I/O cards) already include the essential approvals for railway applications as a product feature – keeping verification and validation work to a minimum. Thanks to its scalability, the PSS 4000-R system can be used for SIL 2, SIL 3 and SIL 4 applications.

Various applications can be implemented using the PSS 4000-R:

· Control functions on rolling stock, such as track laying machinery and traction units to SIL 2/SIL 3

· Control functions/monitoring functions in the signalling area, such as signal monitoring on level crossings, control and safety technology, and signal box connection to SIL 2/SIL 3/SIL 4

The PSS 4000-R system is characterised by a particularly robust design; it meets the increased requirements from the railway sector. Additional benefits include intuitive programming with standardised EN/IEC 61131-3 Editors and Ethernet-based communication.

The PSS 4000-R system is characterised by a particularly robust design; it meets the increased requirements from the railway sector. Additional benefits include intuitive programming with standardised EN/IEC 61131-3 Editors and Ethernet-based communication.

Thales Germany has been using the PSS 4000-R; Mr. Norbert Howe, Director Solutions of the German Business Area Transportation Systems says, “Pilz offers us standardised technology for developing signalling products. Pilz supports us to evolve our relay-based rail signalling products using state-of-the-art components which meet the highest environmental requirements with regards to temperature, EMC and mechanical load. Pilz can provide standard-compliant solutions through to SIL4-capable control systems in accordance with CENELEC 5012x.”

Benefits of PSS 4000-R to the rail sector at a glance:

· A commercially available, off-the-shelf control system from the automation world - expanded to meet the special requirements of the railway - for use in the track area and on rolling stock.

· Special modules with railway approval (CENELEC, TÜV) to the standards: EN 50121-3, EN 50121-3-2, EN 50121-4, EN 50155, EN 50126, EN 50128, EN 50129

· Scalable for safety functions in accordance with SIL 2, SIL 3, SIL 4

· Less work involved for approval, reduced acceptance procedure thanks to the approved system

· High level of independence and transferability due to standardised programming in accordance with EN/IEC 61131-3. What’s more, the Block Editor in the software can be used to create customised blocks, which can be encapsulated/protected and reused at any time. So areas of responsibility and authority can be clearly defined and your applications expertise protected.

· Subsequent modifications: With PSS 4000 it is possible to adapt your architecture retrospectively - thanks to modularisation, reusability of identical components and flexible customisation of hardware and software. So you can expand or retrofit your existing projects at a later date.

· Like other common PLC control systems, PSS 4000-R operates with the usual 24V power supply. However, an input module for a 60V switching level is available specifically for the railway sector.

· Ethernet-based communication: The control systems are networked using the Ethernet-based safety protocol SafetyNETp – long distances of several kilometres can easily be bridged. So the control system in the railway station/signal box can communicate safely with the control system on the level crossing, for example. The system also supports other standardised Industrial Ethernet protocols.

Geen opmerkingen:

Een reactie posten